Agbots: Rise Of The Machines

The sun is shining, thunderheads are just starting to percolate up into a serene blue sky and the smell of freshly tilled soil fills the warm afternoon air.

It’s a great day to be a Florida farmer.

The seed is carefully dropped into the small, perfect hole that’s punched in the tilled soil. A concoction of nutrients is sprayed onto the newly planted seed and loose soil is then scraped carefully over top. The spring planting has gone on nonstop for the last 72 hours—row after endless row planted without a single break for food, sleep or water. In fact, not a single drop of sweat has formed, although a couple of drops of oil did drip onto the fertile soil.

This is no ordinary Florida farmer. This fellow is made out of steel, plastic, circuit boards, plenty of wiring and four rubber tires. This farmer is an agbot, an agricultural robot, and he (or she) (or it) is a machine that can work tirelessly for days or even weeks on end without a single break.

Agbots can till fields while navigating virtually any terrain, plant seeds, water and fertilize plants, test the soil for pH levels, nutrients and moisture content, destroy any weeds that pop up, monitor plant health and harvest the final crop. Of course, they all need some human assistance, but a single machine can now replace a phalanx of human laborers.

21st Century Farmhands

At the turn of the 20th century, a typical farm would be loaded with farmhands, strong men hired to perform the backbreaking labor needed to plant and harvest crops. The farm owner owned the land and called the shots, but the bunkhouse housed the men who made it all happen.

In the brave new agricultural world to come, experts envision an empty bunkhouse. Researchers predict that the average farmer may need one, or possibly two, assistants to help run an entire farm. And what will these new farmhands be required to do?

They will program the machines for the specific job at hand; fuel or charge the machines, if needed; load them with seed, fertilizer, water, insecticide, herbicide or whatever component might be needed at the time; and then monitor the machines for any emergency situations that might arise as they go about the business of farming the land. The rest of the farm work is left up to the machines.

Why Use Agbots?

Agriculture has been around for about 10,000 years. During that time, little has changed in the basics of crop production, but the amount of food produced and the way we farm the land has recently changed tremendously. The steam engine, combustion engine and use of electricity ushered in new eras in farming. Now, it looks as if farming is on the brink of a new revolution—the robotics revolution.

Whereas earlier changes in technology led to changes in farming techniques, these new changes are fueled by another catalyst. Today, the primary factor behind the need to produce food differently is a burgeoning world population. Ten thousand years ago, it is estimated that a mere 5 million people inhabited the planet, and most village groups lived very isolated lives. Today, the world population is at 7.7 billion, and the entire planet is virtually one massive village.

When you take into consideration the fact that it took all of human history up until 1804 for the Earth’s population to reach 1 billion, and now it only takes approximately 12 years to add another billion, it is plain to see that food production must find effective ways to keep pace with all the new, hungry mouths to feed. The world population is projected to be almost 10 billion by 2050, and this will require a 70 percent increase in food production to adequately feed this many people.

One of the ways scientists hope to cope with this looming problem is through technological advances in the field of robotics. Companies like Deepfield Robotics, Case International Harvester and many others, working in conjunction with universities and research institutes worldwide, are producing machines that can work tirelessly and in tandem (either with human farmers who are driving other standard farm machines or with other robotic devices) to tend crops spread over vast areas of land.

What Can Agbots Do?

Scientists are going beyond just creating machines that simply follow human instruction, they are producing machines with what is called autonomous perceptions, the ability of a machine to comprehend its environment and make independent decisions concerning that environment. This type of machine is the product of artificial intelligence research taking place worldwide.

Agbots are presently being developed that can discern the difference between a crop plant and a weed in daylight or total darkness. The machine can then either physically pull the weed out of the soil or spray it individually with a small spritz of herbicide. Researchers estimate that this type of weed eradication uses anywhere from 40 to 90 percent less chemicals than blanket spraying. Some agbots can do the same with insects, spraying a mist of insecticide directly onto individual bugs—once again reducing the use of insecticide by a great percentage.

Agbots can discern obstacles in their path, such as approaching vehicles, humans, farm animals, etc., either stopping to let them pass or going around them and continuing on. Australian researchers have developed solar powered robots that can map entire fruit orchards using lasers, giving farmers precise growth measurements in real time. Other agbots can “look” at individual fruits on a vine or tree, analyze their density and color to determine if they’re ripe and then harvest only the ripe fruit.

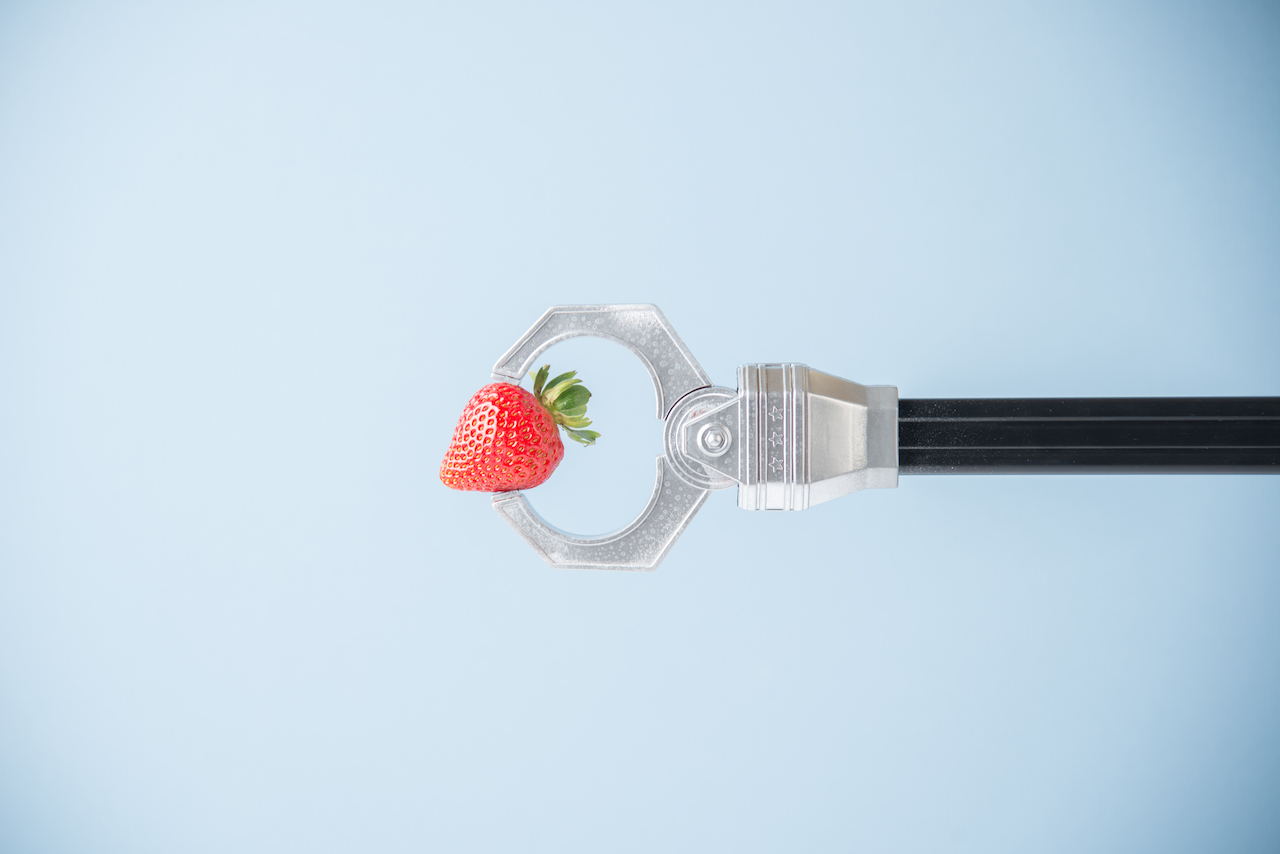

There are also agbots that shear sheep, milk cows, pick fruit as small as a strawberry, graft plants and even debone slaughtered chickens.

Agbots: Who Needs Them?

David Smith is a fourth generation Iowa grain farmer. He, unlike his father, grandfather and great-grandfather, went to college in order to become better acquainted with the business end of farming.

“My father encouraged me to learn the business aspects of the farm. In his father’s day, farming consisted of planting, caring for and harvesting a crop; today’s farmer has to be part scientist, part lawyer, part businessman and then part farmer. Both him and I believe that computerization and robotics will be as important to farming as a tractor in the very near future.”

According to information supplied by the USDA National Agricultural Statistics Service, approximately three-fourths of all the land in Iowa is devoted to growing crops with almost 90,000 farms covering the state. The average size of a farm is around 345 acres, and some cover thousands of acres.

“When most people think of farmers, some still seem to see us walking behind a horse-drawn plow, but farming has really changed in the last century,” says Smith. “Farm size in Iowa keeps growing year after year, and the larger the farm, the more work is required to farm it. Labor is a necessity, and nothing can work harder than a machine. At this time, the technology looks good, and I see the machines starting to appear out there, but the cost has to make it economically sound for us to invest in them. The price of the machines has to equal or be less than the price we pay for human labor to do the same job. I look forward to the day when I work side by side with robotic farm machinery. I mean, I’m up at 4:30, and I finish my day by the headlights of my tractor. But I’m only human, I have to rest, and I can only work so many hours in a week. But these new machines, they will be able to work 24/7. While I am sleeping, my tractors can be ploughing or harvesting. That’s huge. Especially if we’re being pushed by bad weather. I welcome the machines; we’re just waiting for the right price so we can take advantage of all they have to offer.”

Smith explains that the robotic devices being perfected now will definitely take some of the “hands on” out of farming, but that is the trade-off for lower labor expenditures, continuous labor supply and more scientifically precise farming methods that the machines will provide.

“Right now, we’re utilizing what machines we can,” he says. “As soon as they become available and we can afford more, we will definitely be searching the market for the ones we can best use. Two years ago, we bought our first flying drone, and we’ve added another this year. We’re really pleased with the results. We use them to fly over our crops, and they provide us with information as to how healthy our plants are. We can immediately see if they need water or fertilizer or if disease or pests might be present. They are relatively inexpensive compared to satellite imagery or plane flyovers.”

Preparing For The Future

“There’s no doubt in my mind, robots or agbots or whatever you want to call them, are the future of farming,” says Smith. “With the amount of food it’s going to take to feed the entire world in a few years, it will simply be beyond the capability of ‘normal’ farms and farmers to provide it all. I want my sons and their sons to be able to continue to farm our land, but most important of all, I want them to be able to have food on the table to eat for themselves and their families, and without robots on the farm, that may not be possible in another hundred years.”